Clear contracts across your operations

Trusted by over 10000 happy users

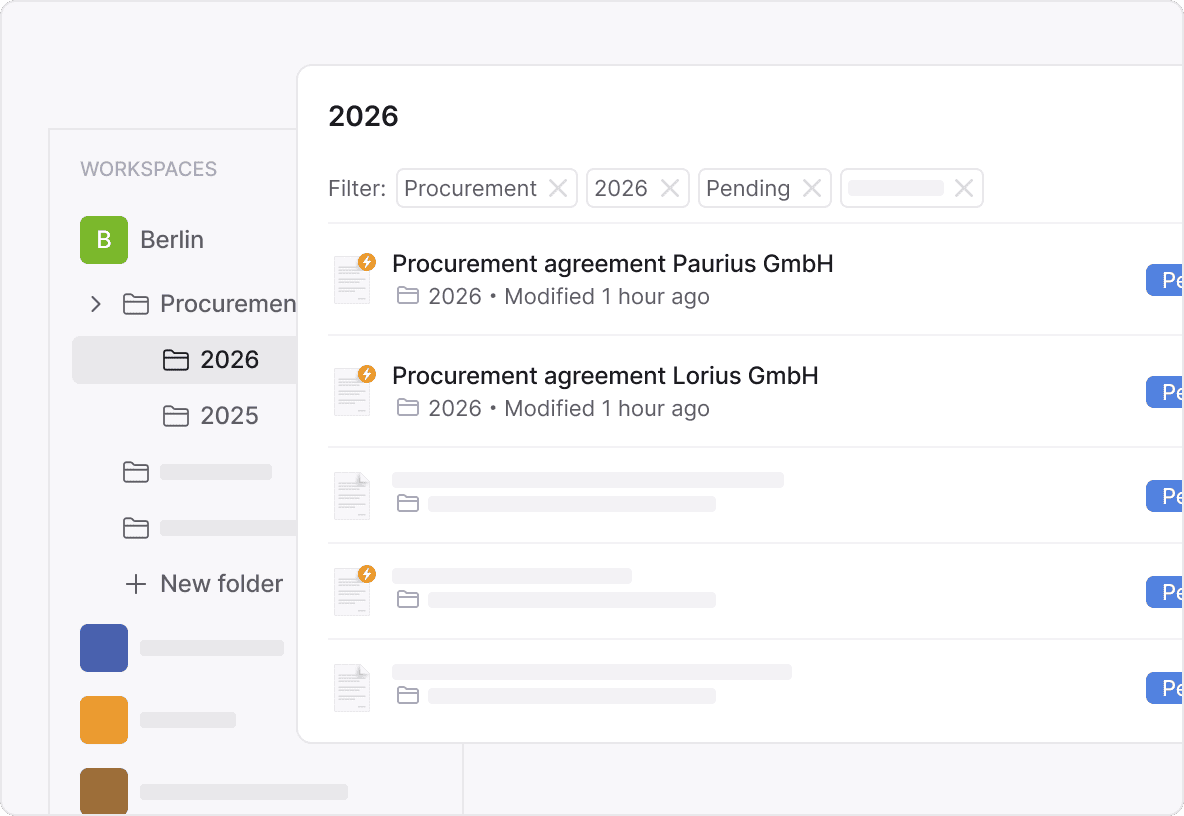

One central contract source across sites and departments

Clear contract versions across teams

Reliable handling of supplier, service, and leasing contracts

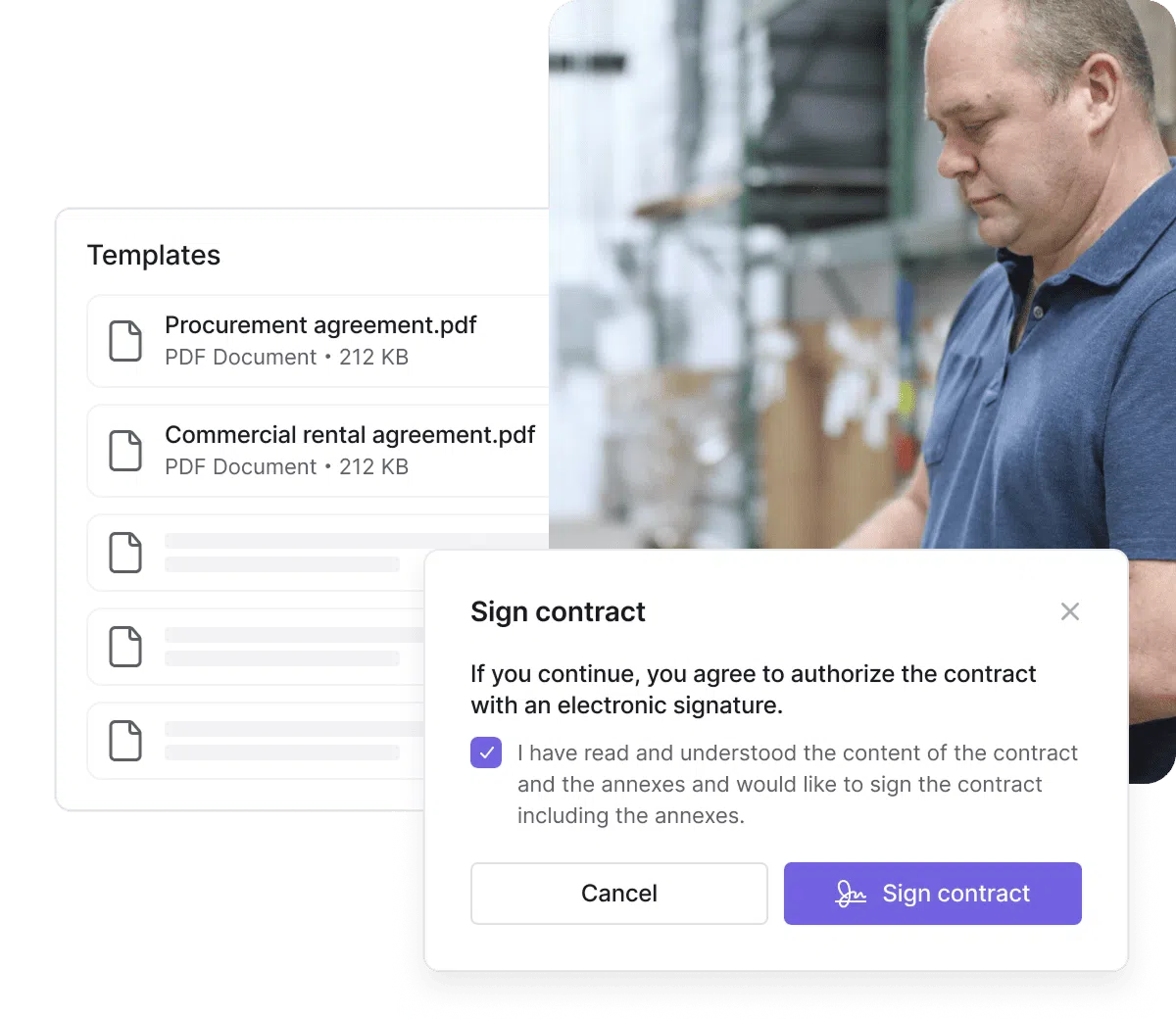

Structured contract workflows for controlled approvals

Automatic tracking of warranties, service, and renewal dates

Transparent contract data for audits and quality requirements

Contract control built for manufacturing environments

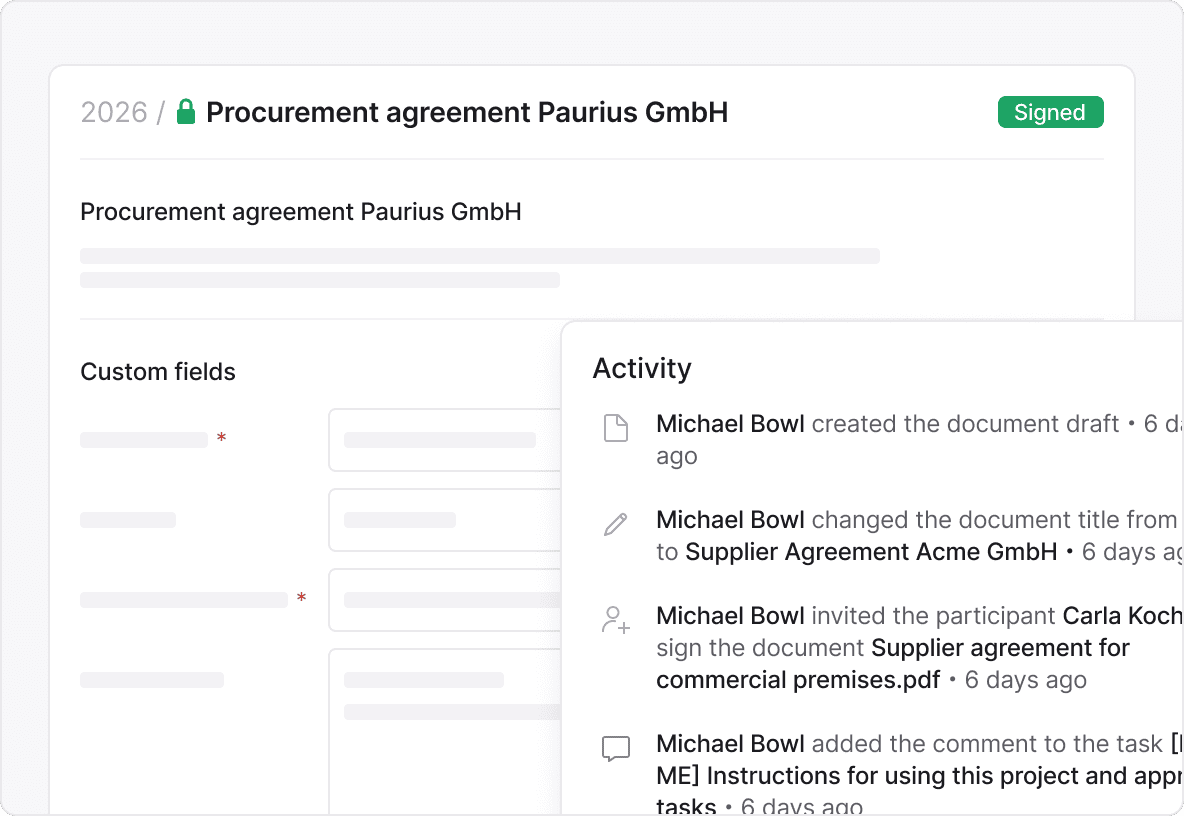

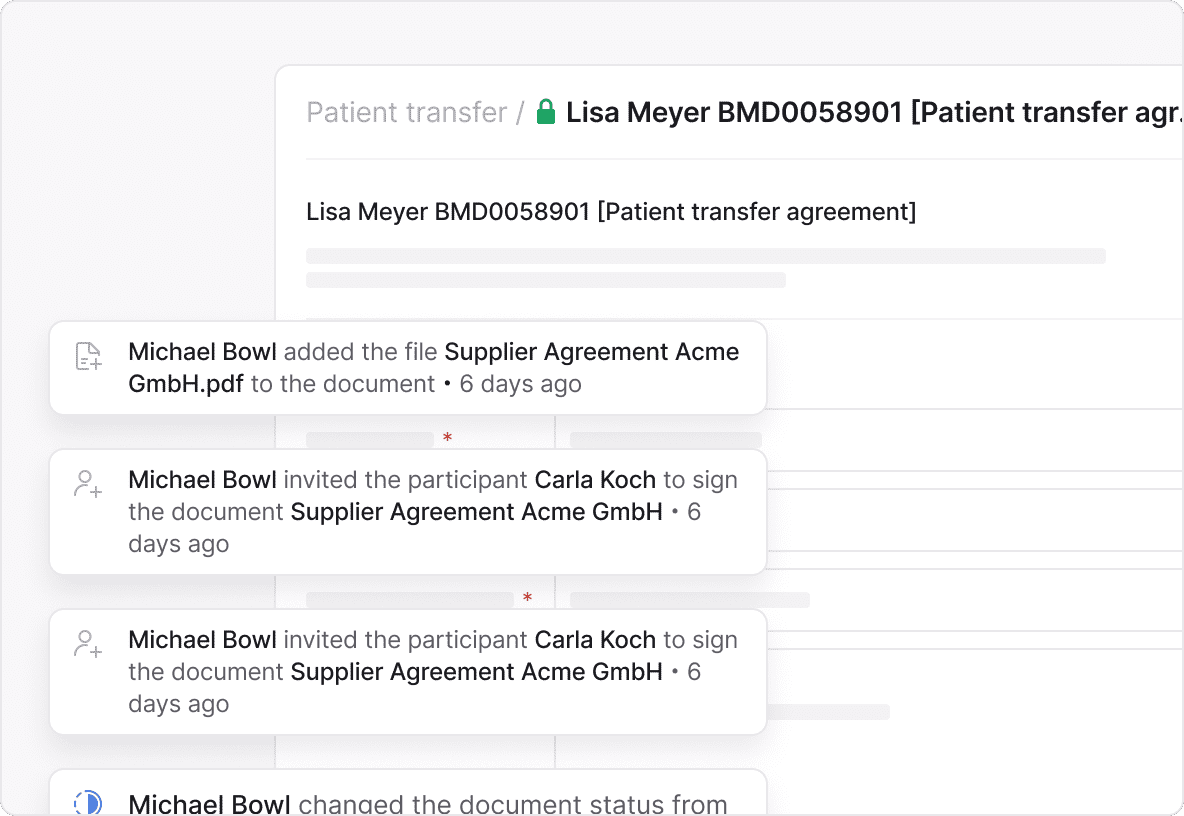

All supplier, service, leasing, and customer contracts are stored with full traceability, approval history, and clear ownership. Every change is documented, every responsibility is visible, and critical terms remain accessible throughout the contract lifecycle.

With Inhubber, contracts support manufacturing operations instead of creating uncertainty. Teams gain confidence that agreements are current, obligations are tracked, and contractual risks are managed consistently across the organization.

Award winning CLM software

Everything you need to work more effectively with contracts

Request a demoFAQ

In manufacturing organizations, procurement, production, and sales often work with the same contracts but from different perspectives. Procurement focuses on supplier terms, production depends on service and delivery conditions, and sales relies on customer agreements. When these teams use different contract versions or store documents in separate systems, misunderstandings and risk increase.

Inhubber provides a single, centralized contract foundation that all departments work from. Every contract has one authoritative version, clear ownership, and full change history. Updates are visible to all relevant stakeholders, ensuring that procurement, production, and sales are always aligned. This reduces internal friction, prevents incorrect assumptions, and creates a shared contractual understanding across the manufacturing organization.

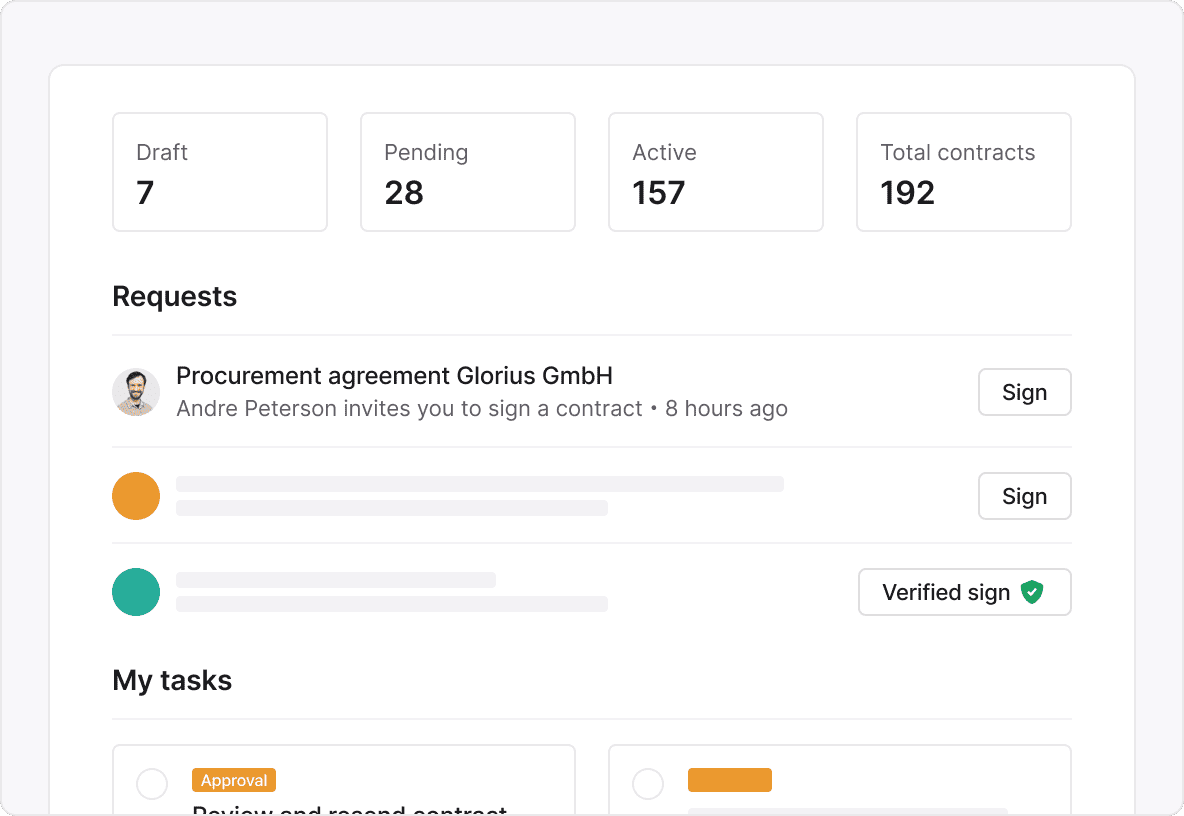

Manufacturing organizations typically manage a large number of supplier, service, leasing, and customer contracts across multiple sites and regions. When these contracts are stored in different folders, systems, or local drives, it becomes difficult to maintain oversight and consistency.

Inhubber centralizes all contracts in one structured repository, making it easier to understand contractual obligations, responsibilities, and timelines. Teams no longer need to search across systems or rely on individual knowledge. Centralization improves transparency, reduces dependency on manual coordination, and creates a reliable foundation for managing contracts across complex manufacturing environments.

Supplier and service contracts are critical in manufacturing, as they directly affect production continuity, maintenance, and cost control. Missed obligations, unclear terms, or outdated agreements can lead to disputes or unexpected expenses.

Inhubber stores all supplier and service contracts centrally with structured data, clear ownership, and tracked changes. Key terms such as service levels, durations, and renewal dates are visible and traceable. This allows teams to manage supplier relationships proactively, avoid overlooked obligations, and maintain contractual clarity throughout long-term partnerships.

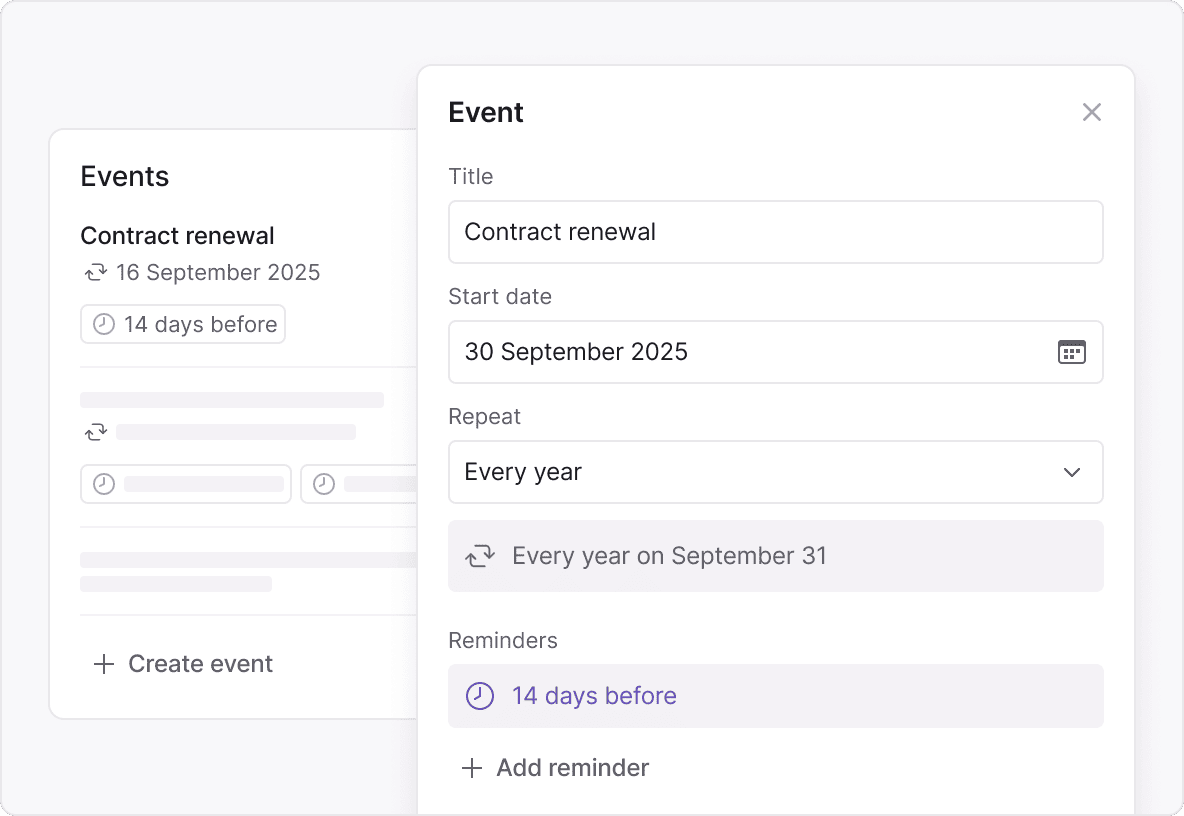

Manufacturing companies often rely on leasing contracts for machinery, vehicles, or technical equipment. These agreements typically include complex terms, service obligations, and fixed end dates that are easy to miss when managed manually.

Inhubber provides full visibility into leasing contracts, including durations, renewal options, and termination deadlines. Automatic reminders ensure that critical dates are not overlooked. By centralizing leasing agreements alongside other contracts, manufacturing teams gain better control over equipment-related obligations and avoid unnecessary costs caused by missed deadlines or unmanaged renewals.

Operational and financial risks in manufacturing often stem from unclear contracts, outdated versions, or missed contractual obligations. These risks may not stop production immediately but can lead to disputes, penalties, or unplanned costs over time.

Inhubber reduces these risks by ensuring that contracts are current, accessible, and traceable. Clear version control prevents teams from working with outdated terms, while structured access and ownership reduce ambiguity. Automatic tracking of key dates and obligations helps organizations stay ahead of potential issues, supporting more predictable and controlled operations.

Manufacturing organizations are frequently subject to audits, certifications, and quality checks that require clear documentation and traceability. Preparing for these reviews is often time-consuming when contracts are scattered across systems.

Inhubber makes contract data transparent and audit-ready by storing all agreements with full access logs, version history, and approval records. Auditors and internal reviewers can quickly verify contract status, changes, and responsibilities. This reduces preparation effort and supports compliance without disrupting daily manufacturing operations.

Contract amendments are common in manufacturing, especially for long-term supplier, service, or customer agreements. Without proper tracking, changes can create confusion and misalignment between departments.

Inhubber manages all amendments within the same contract record, linking them clearly to the original agreement. Every change is documented, approved through structured workflows, and visible to relevant teams. This ensures that everyone works with the same updated information and that contractual changes remain transparent and controlled over time.

Yes. Manufacturing organizations often operate across multiple plants, regions, or countries, each with local suppliers and regulations. Managing contracts consistently in such environments is challenging without a centralized system.

Inhubber supports multi-site and international operations by providing centralized contract management with role-based access. Local teams see what is relevant to them, while headquarters maintains oversight and consistency. This balance allows manufacturing organizations to scale contract management without losing control or clarity.

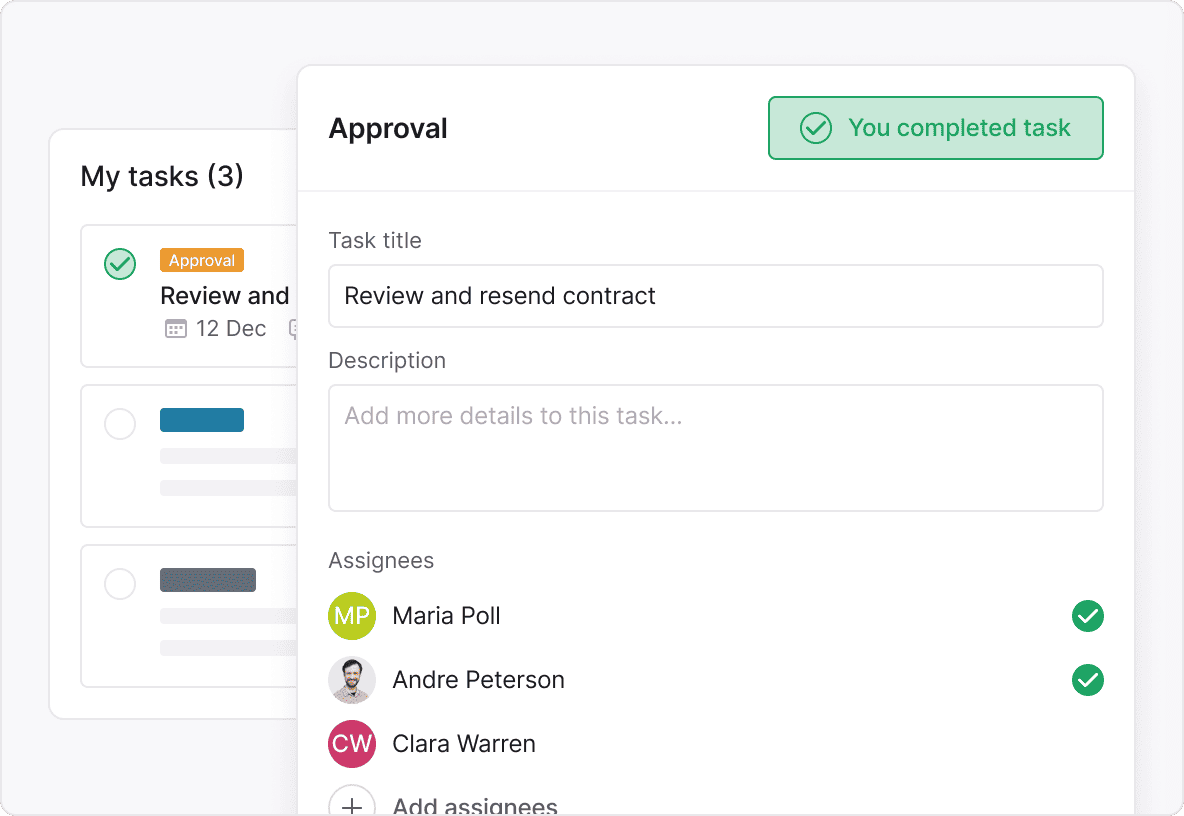

Legal teams play a key role in defining contract standards, but they cannot review every routine contract in manufacturing operations. At the same time, manufacturing teams need flexibility to work efficiently.

Inhubber enables legal teams to define templates, rules, and approval requirements upfront. Manufacturing teams then work within these boundaries, using approved contracts and structured workflows. Legal remains involved where needed, while routine contracts are handled efficiently. This improves collaboration without compromising control or compliance.

Manufacturing relies on long-term relationships, complex supply chains, and clearly defined responsibilities. When contracts are unclear, outdated, or inaccessible, risks accumulate quietly until they result in disputes, downtime, or financial loss.

Inhubber ensures that contracts remain a reliable foundation for manufacturing operations. By centralizing agreements, maintaining clear versions, and tracking obligations, organizations gain confidence that contractual risks are managed proactively. Contract clarity supports stability, predictability, and long-term operational resilience in manufacturing environments.